Estimated reading time: 3 minutes

Proper vent slope and length are essential when venting gas furnaces and water heaters.

A unique vent, known as a type-B, is a double wall pipe used for venting your gas appliance. Since hot rises, the pipe uses a natural draft to expel or ventilate the spent fuel from the appliance. Natural draft refers to the fact that hot air rises naturally, moves through the pipe, and escapes out the top.

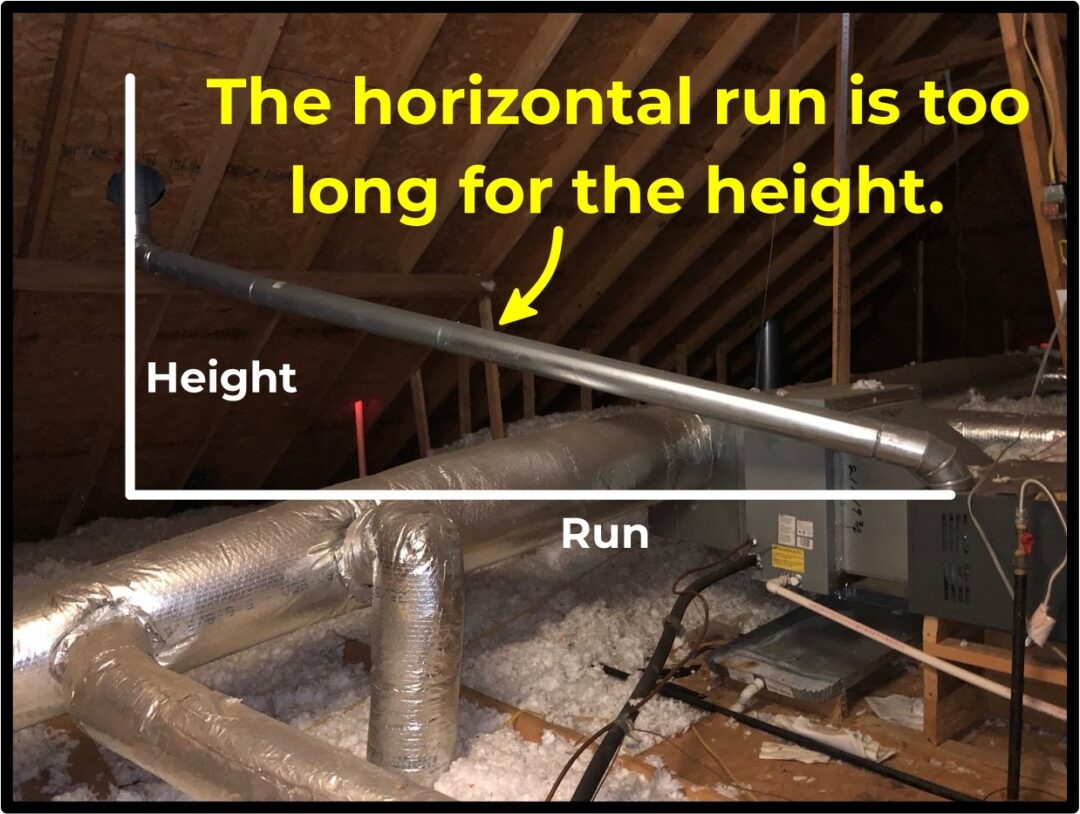

When inspecting a horizontally installed B-vent, there are a couple of things to consider.

- Check the slope of the B-vent pipe: The pipe should be installed with an upward slope of at least 1/4 inch per foot to ensure that developing condensate and flue gases can flow through the pipe. If the pipe isn’t sloped correctly, it may cause air to become trapped and block airflow.

- Check the length: Look to see if a horizontal section or run of the pipe is present. Sometimes called the vent connector, the length should be no longer than about 75% of the finished height of the pipe. This length can vary by manufacturer – but the calculation is considered by many as an accepted rule of thumb.

Trapped gases inside the pipe can corrode the metal and escape into the attic or your home. Look for signs of damage on the top or sides of the pipe. Early warning signs include a white chalky substance beginning to form at the joints or seams in the pipe.

An excessively long B-vent usually causes this poor draft. Cooling combustion gases condense inside the vent, where acidic water vapor causes the galvanized coating on the pipe to corrode. This corrosion can also be caused by poorly mixed fuel and air in an old appliance or a newer furnace that needs maintenance.

In general, it’s recommended to minimize the length of horizontal runs. If you’re unsure about the maximum allowable length of the horizontal run, consult the manufacturer’s specifications or call a qualified heating and ventilation professional.

Gas burner exhaust is mostly carbon dioxide and water vapor, and in modern systems, that moist mix enters the flue at a temperature not far above its dew point of 140°F. If the moisture hits a cool surface, or just takes too long to reach the top of the system, it’s likely to condense — and because the vapor contains trace amounts of oxides of nitrogen, the condensate is a weak nitric acid solution that can corrode masonry or metal.

Bob Dwyer is a technical trainer for Bacharach, Inc. Mark Gronley is a quality control supervisor for Northwestern Energy, a Montana utility. They have cooperated in preventing and fixing combustion-related problems in homes sincethe early 1980s.

If you want to get technical, here’s a much more detailed explanation of the issues we’re talking about, written 20 years ago in the Journal of Light Construction by Bob Dwyer & Mark Gronley. Their content is still relevant today.

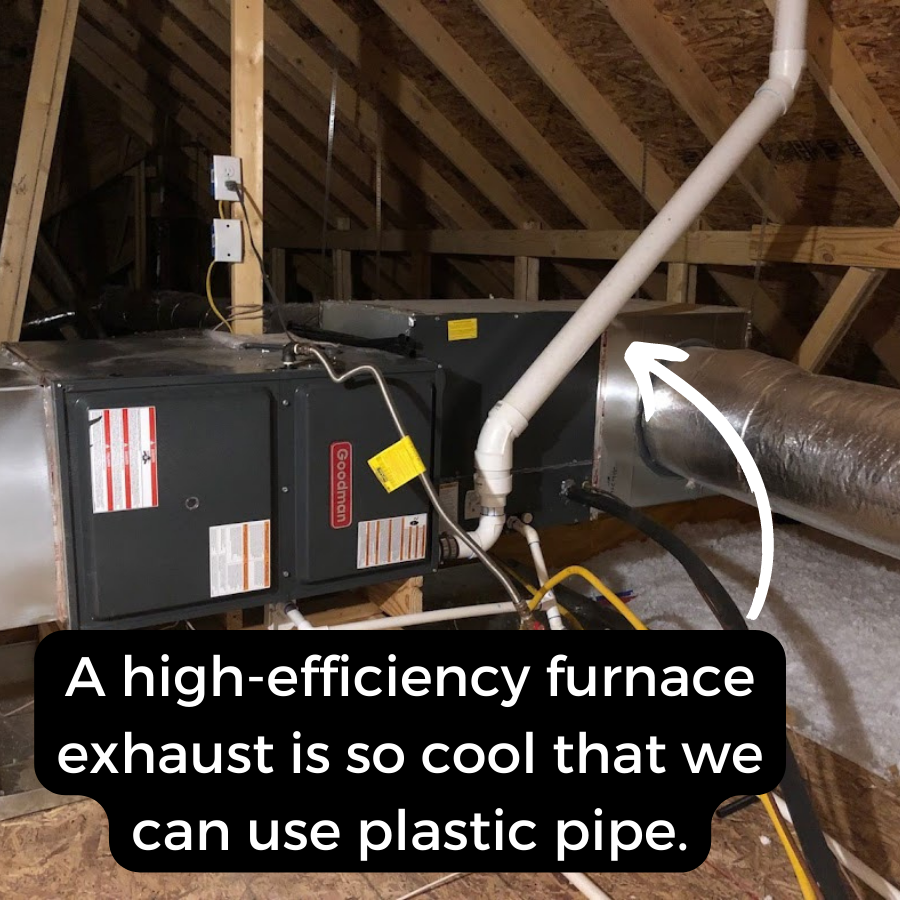

A few photos of vent types and conditions I’ve inspected.

- - - - - - - - - - - - - - - - - - - - -