History1Wikipedia Article

Frank Adam Electric, a manufacturer of electrical panels and circuit breakers, was founded in 1891 as part of the Blacker and Adam Watch Company in St. Louis, Missouri. In 1928, a young sales manager named Emile Zinsmeyer took charge of Frank Adam Electric’s western division in Los Angeles. In the latter part of the Great Depression, Emile negotiated to buy Frank Adam’s west coast stock, forming the Zinsmeyer Company.[1] Frank Adam Electric continued manufacturing panels and breakers through the 1950s, and they are now extremely rare.

Located at 729 Turner Street in Los Angeles, the Zinsmeyer Company would soon undergo some changes. Zinsmeyer employed two sons, Wilford, who went by Bill, and Martin. In 1943, Martin bought the company from his father and renamed it Zinsco Electric. Almost immediately, Zinsco began the development of new panel and circuit breaker designs, with patent applications dating back to 1946. The first Zinsco panels contained copper bus bars and copper breaker clips. Original breakers were patented in 1950 and labeled “Magnatrip.” Five additional patents would be issued for subsequent designs. These early breakers used copper bus clips to match the panels’ copper bus bars.

Copper/Aluminum

Before World War II, the only permissible electrical conductors were copper, gold, and silver. A copper shortage during the war promoted code changes. Although aluminum was initially expensive to manufacture, advancements in the processing and production of aluminum wire made it available by 1942, and it was added to the National Electrical Code. In 1952, the Korean War caused another major copper shortage in the U.S. Although some companies, such as FPE and Square-D, continued to use an all-copper design, other manufacturers switched to an aluminum alloy for bus bars and breakers. Zinsco would remain with copper in their panels and breakers until the third major copper shortage in the early 1960s when they switched to an aluminum bus. In 1963, Zinsco introduced the R-38 twin breaker, the only twin circuit breaker that also made contact on both bus bars for 240 volts in a single breaker space. This made the Zinsco brand hugely popular with contractors, and millions of Zinsco service panels and load centers were installed through the 60s and 70s.

In 1973, Martin Zinsmeyer sold the Zinsco Electric Company to GTE-Sylvania. The product line remained the same during that ownership, with new labeling and branding, while dropping the “Magnatrip” label. In 1978, the line changed names again and was re-labeled as Challenger.

Jackson, Mississippi Manufacturing Plant

By 1981, GTE-Sylvania divested itself of the electrical distribution business and sold its product lines and manufacturing facilities. The Challenger line, mostly manufactured at the time here in Jackson, Mississippi, was sold to a former officer of GTE, who used the Challenger name as the name of his new company, Challenger Electrical Equipment Corporation.

The new Challenger Brand immediately ceased production of any new Zinsco frame panels and load centers but still produced the re-branded Zinsco circuit breaker line. Challenger concentrated on a new line of panel equipment using the same bus configuration proven with Murray, Crouse-Hinds, and others. But, from 1982 until 1994, the 200-amp service panels used a Zinsco frame main breaker. Challenger flourished through the 80s and was eventually received by Westinghouse in a multi-asset deal for Westinghouse to sell its remaining electrical manufacturing facilities to Eaton Corporation in 1994. Both Challenger and Thomas & Betts (T&B) had manufacturing facilities in Mississippi, where T&B received the Zinsco circuit breaker molds. T&B then continued to fabricate and sell the breakers under their label, tripling the price from about $7.00 for the popular R-38 twin breaker to $19.00. T&B would eventually close the Zinsco circuit breaker production altogether in 2005. Today, Connecticut Electric continues making Zinsco replacement aluminum bus kits and breakers.

Safety Concerns

The Zinsco line has been the subject of numerous recalls and safety concerns due to problems with the design and performance of the panel’s circuit breakers.

One of the main issues with Zinsco electrical panels is that the circuit breakers tend to fail to trip when they should, which can lead to electrical fires. In addition, the panel’s aluminum bus bars, used to distribute electricity to the circuit breakers, have corroded and caused problems with the panel’s performance.

Due to these safety concerns, Zinsco electrical panels are no longer widely used and are not recommended for use in new construction or as a replacement for existing panels. If you have a Zinsco electrical panel in your home or building, it is important to have it inspected by a qualified electrician to determine if it is safe to use. The panel should be replaced with a newer, more reliable model if necessary.

Watch this video that shows how the breaker won’t trip to shut the power down.

Distinguishing Characteristics

Zinsco electrical panels were known for their distinctive design and appearance. Some of the distinguishing characteristics of Zinsco panels include the following:

- Size and shape: Zinsco panels are typically rectangular and are available in a variety of sizes to accommodate different numbers of circuits.

- Aluminum bus bars: Zinsco panels used aluminum bus bars to distribute electricity to the circuit breakers. These bus bars were known to corrode over time, which could cause problems with the panel’s performance.

- Circuit breakers: Zinsco panels use a circuit breaker designed to trip and interrupt the flow of electricity in the event of an overload or short circuit. However, these circuit breakers were prone to failure and were linked to numerous electrical fires.

- Age: Zinsco panels are no longer being manufactured, so any panel still in use is likely to be quite old. This can be a distinguishing characteristic of Zinsco panels, as most other panel brands have been updated with newer models.

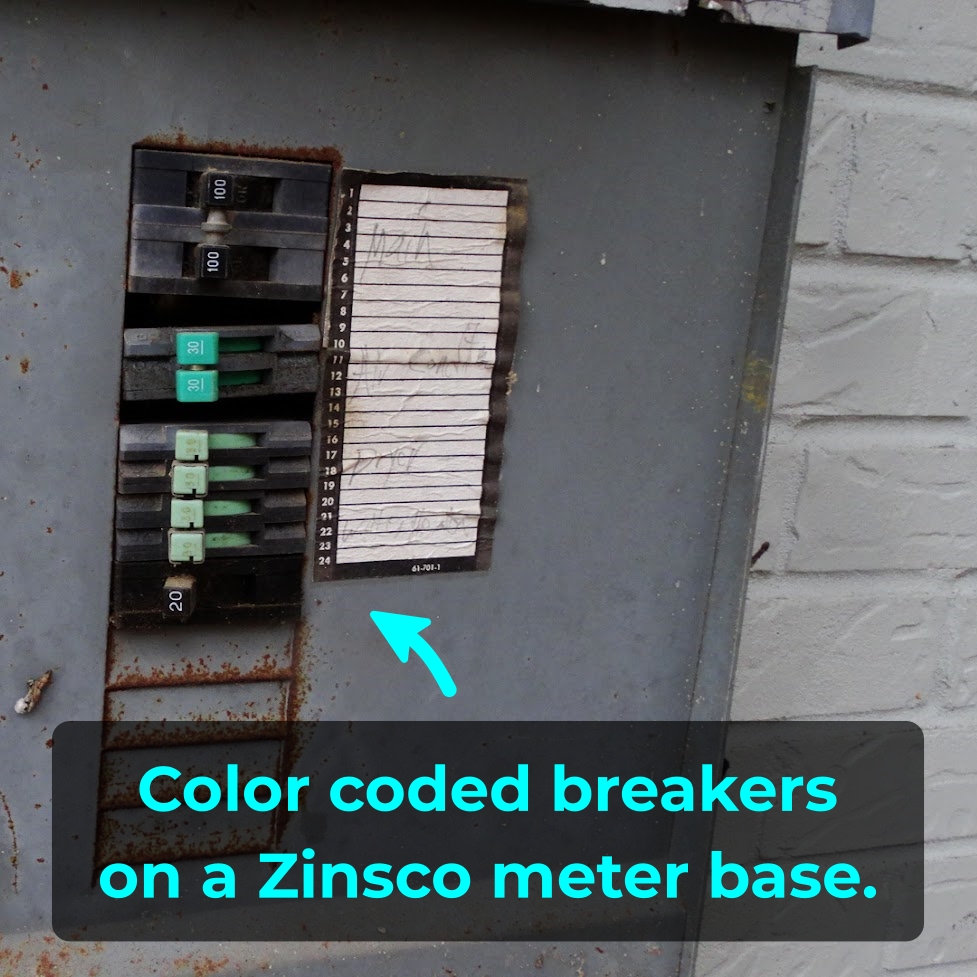

- Top Hinged Cover: The Zinsco meter base dead cover is hinged to open and swing from the top.

Color-coded Breakers

The circuit breakers in Zinsco electrical panels were often color-coded to indicate the size and type of breaker. The specific colors used may vary depending on the model and age of the panel, but some standard color codes for Zinsco circuit breakers include:

- 15 Amp – Blue

- 20 Amp – Red or Orange

- 30 Amp – Green or Light Blue

- 40 Amp – Grey or Light Brown

- 50 Amp – Black

- 60 Amp – White

- All Amps could be black (for the full-size QC line)

My Recommendation

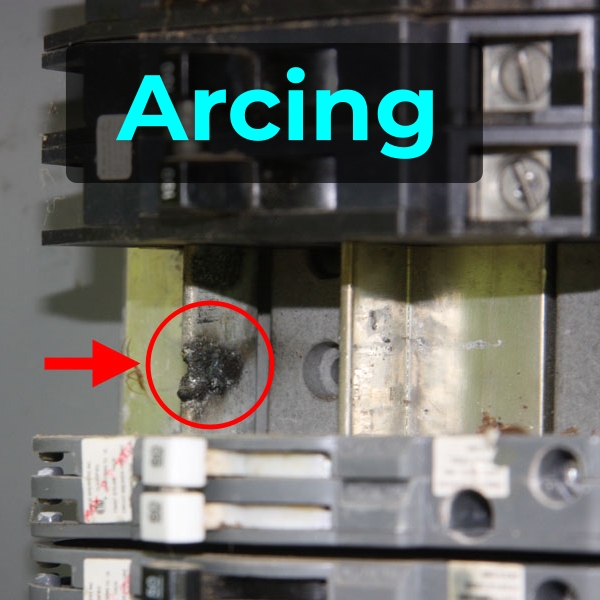

Zinsco electrical equipment is considered obsolete due to a design flaw in which the circuit breaker’s connection to the bus bar becomes loose, causing arcing and subsequent overheating. Long-term exposure to this heat can cause the breaker to fuse to the bus bar, making it impossible to remove. Even worse, it can cause the breaker’s contacts to fuse, thus preventing the breaker from tripping even in an overcurrent situation, thereby causing a potential fire hazard. Some homeowners’ insurance will not cover the risk of a Zinsco panel installed in the home. I recommend you have the panel evaluated by a licensed electrician with experience handling this brand system.

References

This Article's Footnotes/References

- 1

- - - - - - - - - - - - - - - - - - - - -