Estimated reading time: 10 minutes

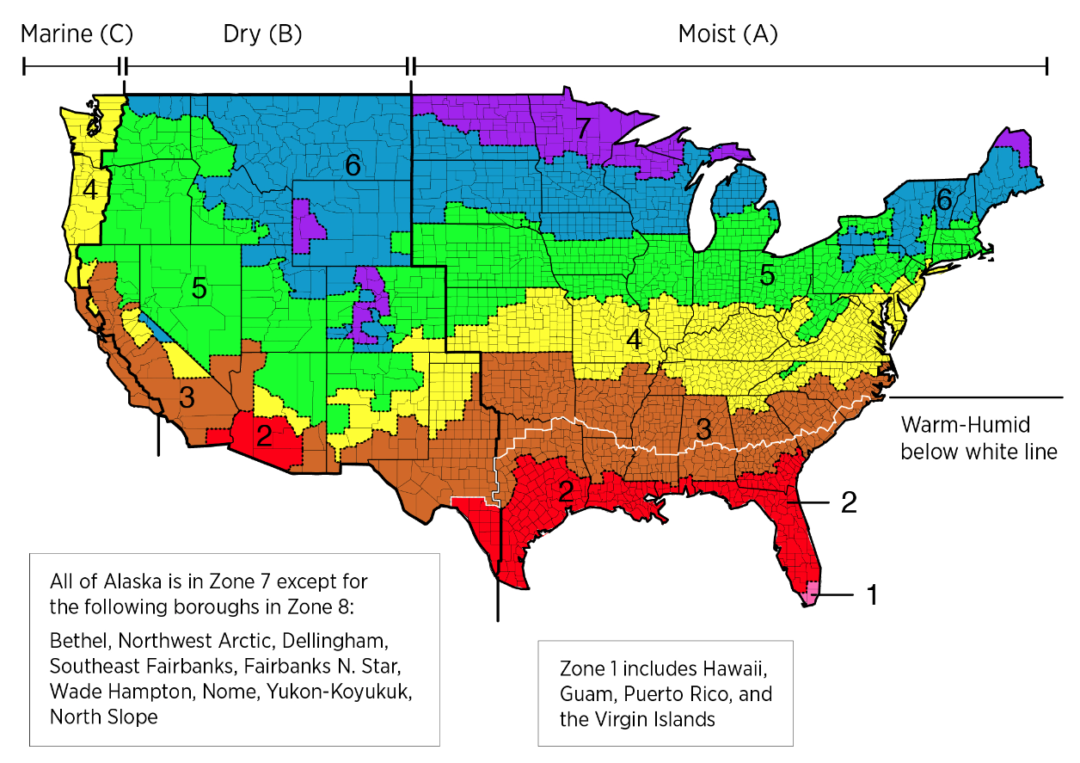

Most Mississippians live in climate zone 3, and pipe insulation is at the core of the defense against freezing temps. This thermal barrier can help slow heat loss to its colder surroundings.

However, don’t assume your new home meets the minimum standard for pipe insulation. As a matter of fact, most homes here don’t have pipe insulation. Huh? None? – – – Yup – – none.

The U.S. is categorized into various climate zones by the International Energy Conservation Code (IECC). Although Climate Zone 3 is considered “hot humid,” we aren’t exempt from the occasional cold snap. And, like our wind (aka – tornados), when we get a cold snap, it can be a real budget buster.

Most building officials in Mississippi have omitted the energy chapter of the building code (Chapter 11). That means your building department has chosen to “not adopt” entire chapters of the building code.

You guessed it – Chapter 11 is where the rule for hot water pipe insulation is located.

That chapter also has a host of important minimum standards dealing with your home’s efficiency. It talks about duct leakage rates, air infiltration of the building, how to measure the building’s “leakiness,” and more.

The presence and/or thickness of pipe insulation on hot water pipe is one of the standards that isn’t enforced in most code jurisdictions of Mississippi.

R-3 INSULATION AND THE BUILDING CODE

The minimum standard for pipe insulation of hot water pipes in Climate Zone 3 is R-31(2018). International Residential Code. International Code Council, Inc. https://codes.iccsafe.org/s/CTRC2022P1/chapter-11-re-energy-efficiency/CTRC2022P1-Pt04-Ch11-SecN1103.5.2. The rule attempts to address the energy component of the code. The code states it’s more energy-efficient to insulate hot water pipes.

Let’s move to the plumbing chapter.

In the Plumbing Chapter 26 of the IRC, section P2603 Structural and Piping Protection – P2603.5 Freezing states: In localities having a winter design temperature of 32°F (0°C) or lower as shown in Table R301.2 of this code, a water, soil or waste pipe shall not be installed outside of a building, in exterior walls, in attics or crawl spaces, or in any other place subjected to freezing temperature unless adequate provision is made to protect it from freezing by insulation or heat or both.

Based on table R301.2, the 97 1/2-percent value for winter indicates a 25°F temperature for central Mississippi. 25°F is below 32°F.

The uniform building code isn’t the only set of rules that require pipe insulation:

2021 IAPMO Uniform Plumbing Code (UPC) [unchanged since 2015] 312.6 Freezing Protection. “No water, soil, or waste pipe shall be installed or permitted outside of a building, in attics or crawl spaces, or in an exterior wall unless, where necessary, adequate provision is made to

protect such pipe from freezing.”

2021 IAPMO Uniform Mechanical Code (UMC) [unchanged since 2015] 1210.1 Piping, Tubing, and Fittings. “Hydronic pipe and tubing shall comply with the applicable standards referenced in Table 1210.1 and shall be approved for use based on the intended purpose. Materials shall be rated for the operating temperature and pressure of the system and shall be compatible with the type of heat transfer fluid. Pipe fittings and valves shall be approved for the specific installation with the piping materials to be installed and shall comply with the applicable Standards referenced in Table 1210.1. Where required, exterior piping shall be protected

against freezing, UV radiation, corrosion and degradation. Embedded pipe or tubing shall comply with Section 1221.2.”

1215.3 Freeze Protection. “Hydronic systems and components shall be designed, installed and protected from freezing.”

1220.4 Snow and Ice Melt Controls. “An automatic thermostatically operating control device that controls the supply hydronic solution temperature to the snow and ice melt area shall be installed in the system. Snow and ice melt systems shall be protected from freezing with a mixture of propylene glycol or ethylene glycol, and water or other approved fluid. Automotive antifreeze shall not be used.”

2018 IAPMO Uniform Solar, Hydronics and Geothermal Code (USHGC)

401.8 Freeze Protection. “Hydronic systems and components shall be designed, installed, and protected from freezing.”

408.1 Pipe, Tube, Tubing, and Fittings. “Hydronic pipe and tubing shall comply with the applicable standards referenced in Table 408.1 and shall be approved for use based on the intended purpose. Materials shall be rated for the operating temperature and pressure of the system and shall be compatible with the type of heat transfer fluid. Pipe fittings and valves

shall be approved for the installation with the piping, materials to be installed and shall comply with the applicable standards referenced in Table 408.1. Where required, exterior piping shall be protected against freezing, UV radiation, corrosion and degradation. Embedded pipe or tubing shall comply with Section 417.2.”

416.1 Snow and Ice Melt Controls. “An automatic operating control device that controls the supply hydronic fluid temperature to the snow and ice melt area shall be installed in the system. A means shall be provided to prevent low return hydronic solution temperature in accordance with Section 410.4. Snow and ice melt systems shall be protected from freezing with a mixture of propylene glycol and water, or other approved fluid.”

501.12 Freeze Protection. “Unless designed for such conditions, solar thermal systems and components that contain liquid as the heat transfer medium shall be protected from freezing where the ambient temperature is less than 46°F (8°C) by means of fail-safe in accordance

with Section 501.12.1 through Section 501.12.5.”

2021 ICC International Mechanical Code (IMC) [unchanged since 2015]

1402.4 Protection from freezing. “System components shall be protected from damage by freezing of heat transfer liquids at the lowest ambient temperatures that will be encountered during the operation of the system. Freeze protection shall be provided in accordance with ICC

900/SRCC 300. Drain-back systems shall be installed in compliance with Section 1402.4.1 and systems utilizing freeze-protection valves shall comply with Section 1402.4.2.”

2018 National Standard Plumbing Code (NSPC)

2.16 FREEZING OR OVERHEATING a. “The plumbing system shall be

protected from freezing or overheating. The following conditions shall be

met”

- “In areas with seasonal freezing outdoor temperatures, all drain piping

and water piping installed in exterior walls, attics, and other areas exposed

to outdoor temperatures shall be protected from freezing. In heated

spaces, the piping shall be installed on the heated side of the building

insulation.”

Builders and remodelers should incorporate protective measures against freezing pipes in new and remodeled buildings. Home inspectors and building consultants should make appropriate recommendations based on the inspection results. I recommend a minimum R-3 insulation wrap on an exposed pipe in Central Mississippi.

While prolonged exposure to freezing temperatures can challenge even insulated pipes, the right insulation can often fend off freezing temperatures, especially during our short cold spells.

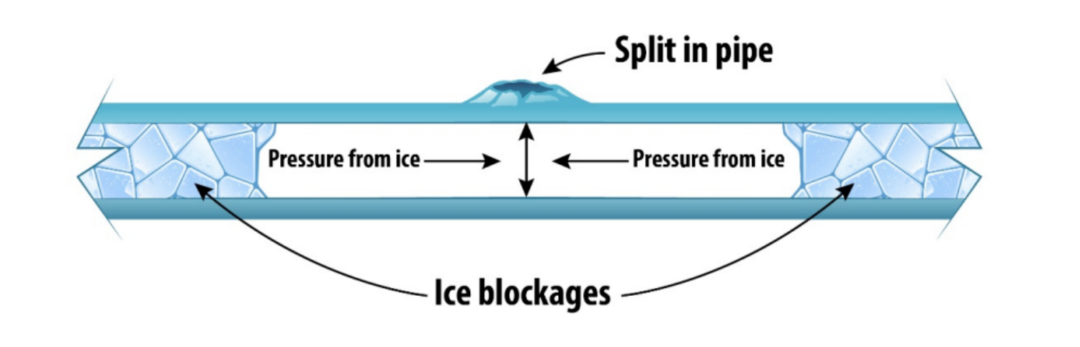

Pipe type, lack of insulation, and improperly installed insulation are consistently identified as leading causes of freezing pipes and, subsequently, insurance claims for water damage.

PIPE MATERIAL

Now, let’s talk materials. Different pipes have distinct freezing susceptibilities. Spoiler alert: PEX pipe performs best; however, the fittings and their construction are where most leaks occur in PEX plastic pipe.

Copper, an excellent heat conductor, can quickly lose heat. ALWAYS insulate copper pipe, as it’s the most common pipe type in climate zone 3 to suffer freeze damage.

Plastic pipes, like PVC and CPVC, might resist freezing a tad longer than copper but can become brittle in extreme cold.

PEX pipes are made of a cross-linked polyethylene material that is very flexible and has the highest tolerance to freezing. PEX pipes are also very durable and can withstand high temperatures and pressures. I’ve written about whether freezing temps will damage pex pipe.

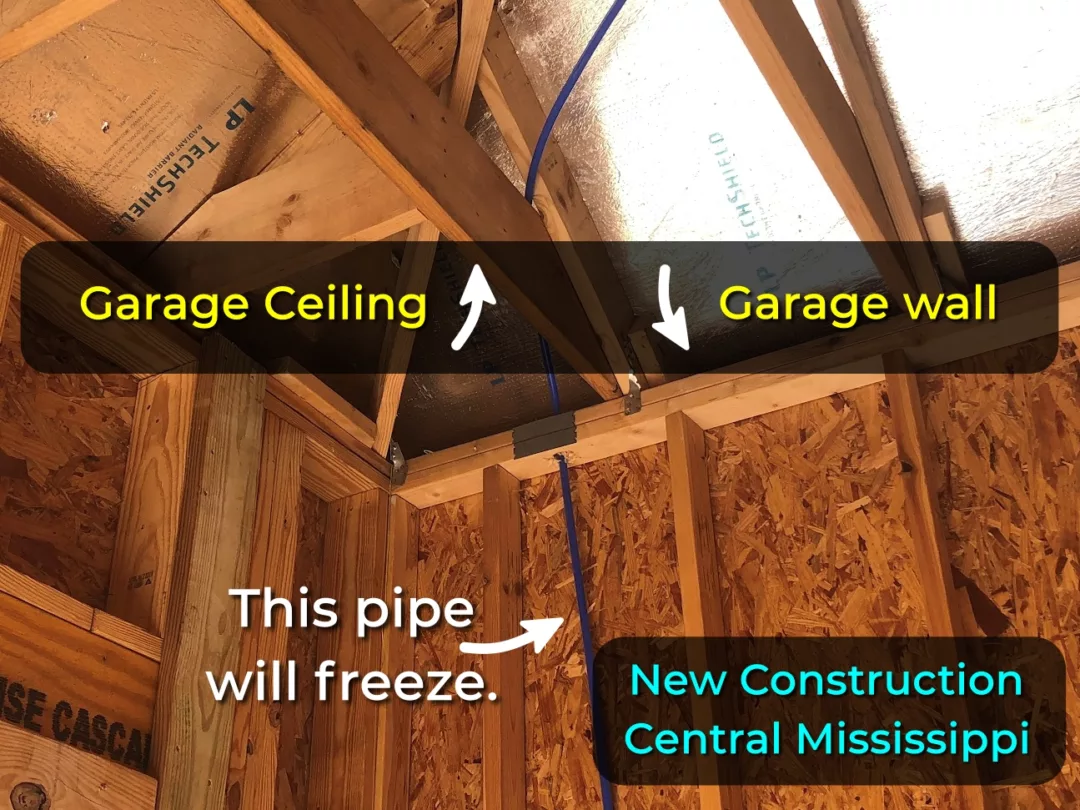

I often note PEX pipe in attics subjected to freezing temps (photo at right), especially when installed in exterior walls of a garage or storage room built without wall cavity insulation.

Galvanized steel pipes, though less common in homes these days, have their own challenges, including corrosion. Galvanized pipes are prone to freezing. Most galvanized piping has a compromised interior surface caused by corrosion. In most cases, I recommend this pipe type be replaced when used as a potable water supply pipe.

PIPE INSULATION

There are many different types of pipe insulation available, but the most commonly used in Climate Zone 3 is foam. Look for a minimum value of at least R-3. Most insulation can be cut with shop scissors or a utility knife. If the product doesn’t have a self-seal feature (see below), the best method of sealing the seam is to use a clip (shown at the right) or a snap tie. Snap ties are durable, resistant to temperature changes, and can be wrapped around the insulation to keep it in place. Take care they’re not pulled so tight that they compress the insulation, as this can reduce the insulation’s effectiveness.

Don’t use duct tape. The glue on duct tape is not designed for our hot attics and will lead to insulation wrap failure.

- Fiberglass: Fiberglass is a versatile and affordable insulation that reduces heat loss. It is available in various thicknesses and can be easily installed on pipes of all sizes. Although the cheapest type of insulation, one of the challenges of using fiberglass includes the loss of thermal protection when it’s tightly wrapped. When fiberglass is squeezed tight, it loses its ability to protect against cold temps.

- Foam: Foam is the most popular choice for pipe insulation. It is lightweight and easy to work with, and it provides good thermal resistance. Foam insulation is available in both rigid and flexible forms. The one at right self-seals. Measure the pipe diameter. Most foam is sold in 6′-0″ foot lengths. It won’t perform well when wet – if you’re trying to protect a pipe installed in a wet location, I suggest rubber insulation.

- Rubber: Rubber insulation is a good choice for pipes that are exposed to the elements or that are likely to be bumped or jostled. It is durable and weather-resistant and provides good thermal resistance. Rubber insulation is available in various thicknesses and can be easily installed on pipes of all sizes. You’ll pay more for the rubber type.

HOT WATER FREEZES FASTER THAN COLD

The Mpemba effect is the name given to the observation that a liquid (typically water) which is initially hot can freeze faster than the same liquid that began as cold, under otherwise similar conditions2Wikipedia. 2023. “Mpemba Effect.” Wikimedia Foundation. Last modified October 3, 2023. https://en.wikipedia.org/wiki/Mpemba_effect. Several theories attempt to explain this, from rapid evaporation in hot water reducing its mass to the release of dissolved gases, affecting freezing characteristics.

The recent fad of making “instant snow” on chilly days by throwing boiling water up into the air is a manifestation of the Mpemba Effect3Salinas, K. (2015, January 18). Unsolved Mysteries: The Mpemba Effect. Yale Scientific. https://www.yalescientific.org/2015/01/unsolved-mysteries-the-mpemba-effect/.

Convection currents in hot water and the possibility of supercooling in cold water add further layers to this enigma. While this effect presents an intriguing scientific puzzle, its real-world impact on our plumbing is debatable.

STAY WARM

Factors like pipe insulation quality, airflow around the pipes, and water’s initial temperature play significant roles in freezing.

In conclusion, for us in Climate Zone 3, while the threat of freezing pipes isn’t an everyday concern, it’s vital to be prepared for those colder days. Ensure your pipes are well-insulated, and familiarize yourself with the materials used in your home.

Remember, knowledge is your best tool in maintaining a safe and efficient household. Stay informed and stay warm.

This Article's Footnotes/References

- 1(2018). International Residential Code. International Code Council, Inc. https://codes.iccsafe.org/s/CTRC2022P1/chapter-11-re-energy-efficiency/CTRC2022P1-Pt04-Ch11-SecN1103.5.2

- 2Wikipedia. 2023. “Mpemba Effect.” Wikimedia Foundation. Last modified October 3, 2023. https://en.wikipedia.org/wiki/Mpemba_effect

- 3Salinas, K. (2015, January 18). Unsolved Mysteries: The Mpemba Effect. Yale Scientific. https://www.yalescientific.org/2015/01/unsolved-mysteries-the-mpemba-effect/

- - - - - - - - - - - - - - - - - - - - -