Assuming proper installation and common sense building techniques, let’s address the myth that freezing temperatures won’t damage/ruin Cross-Linked Polyethylene – PEX pipe.

Spoiler Alert: It depends.

Pex has revolutionized plumbing installations in new home construction and remodeling.

Safe for potable water, PEX is the red and blue flexible tubing used to make gentle bends around obstructions in your attic and is perfect for adding water supply to hard-to-reach locations.

New fad?

No, expect the product to last upwards of 40 – 50 years (as compared to type L copper, which lasts 50 to 100 years). Many European plumbing systems are still intact and operational after 30 years of installation.1 Pex tubing myths and facts. Like any product, some best-use practices exist. For instance, operating temperatures: from 180 degrees (the top setting on your water heater) to below-freezing 20 degrees. Any colder than that – it’ll start stopping up! But will it BURST?

Freezing Temps

The insurance industry reports that over a quarter-million homeowners annually suffer property damage from broken supply pipes, many from freeze events.2 Water Damage Claims Stats PEX offers a potential advantage over rigid plumbing such as copper or hard PVC. Due to its flexibility (polymers), PEX has a small expansion margin under the damaging pressure caused by ice formation.

If the weather gets cold enough, like any plumbing, PEX pipes can and will freeze. However, PEX may be less likely to rupture due to freezing. Manufacturers won’t provide a guarantee against rupture. But the failure may not be from expansion – it may be a combination of freezing temps and the age of the pipe.

How To Help Prevent Freezing PEX

Follow these steps to prevent PEX pipes from freezing in your home:

1. Are you designing your home now? Route PEX pipe through the interior – not exterior – walls where possible.

2. Keep rooms at 55 degrees or more when outdoor temps drop below 20 degrees.

3. Insulate PEX pipe exposed to freezing temperatures. U.S. DOE recommends pipe insulation with a minimum of 3.0 R-value (~ 3/8” thick insulation walls). Select localities (colder climate zones) recommend an R-value of 4.0 and above (~ 5/8” walls).

4. During spells of acutely cold weather, allow indoor faucets to dribble and relieve damaging pressure in pipes if ice forms.

5. Have a vacation home? Drain the entire plumbing system when winterizing a summer home or a house where plumbing is not used in winter.

6. PEX pipe storage. Keep PEX away from sunlight. Like most other plastics, PEX will become brittle if exposed to sunlight for too long and may crack under pressure. The typical exposure limit is ~30 days. Check with the manufacturer.

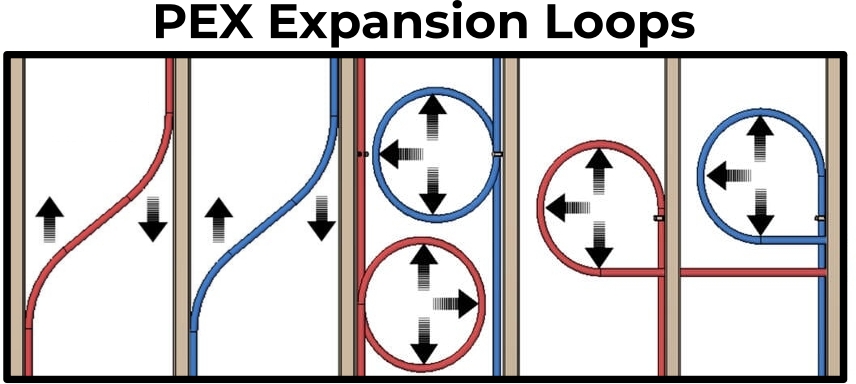

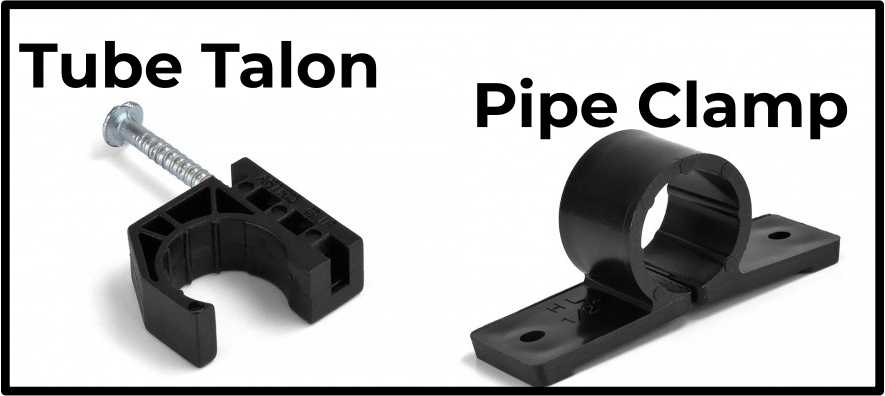

7. Give it some slack! Since PEX will expand and contract 1-2.5” per 100 feet of length with every 10°F change in water temp, it should not be pulled tight during the installation. In case of a 60F temperature rise, 100 feet may elongate as much as 15”. Use tube talons and pipe clamps that allow pipe movement without damaging it and form expansion loops on long runs of pipe that carry hot water. Failure to properly secure the pipe will overstress it and may cause mechanical damage, even ruptures. The Minimum recommended bending radius is eight times the outside diameter (8 x OD). Example – for 1/2″ PEX with OD of 5/8″, minimum bending radius is 8 x 5/8″ = 5″. Overbending the PEX pipe deforms its’ round shape, restricts flow, and over-stresses the pipe. Note: minimum bending diameter only refers to the 90-degree and 180-degree (U-shaped) bends. Parallel runs of pipe can be spaced as close as necessary.

Unfortunately, the ability of PEX to expand can decrease significantly as the material ages and begins to oxidize due to common water disinfectants such as chlorine, chloramine, and chlorine dioxide.

Jonathan Simon – FlowGuard Gold

I live in Mississippi and have a run of PEX in my attic that freezes when the outdoor temps fall to about 15 degrees. Once my attic warms up (after a few hours the next day), the pipe thaw. So far, no leaks.

PEX won’t ruin if frozen. There are NO manufacturer guarantees it won’t fail. It’s wise to insulate water supply piping exposed to freezing temp. The cost will run about $.50 – $.70 per foot. Look to spend about $75 to $150 to insulate pipe in the attic of a 2-bath home. Don’t forget your labor!

Resistance to Chlorine and Chloramines3Page 15 – Residential PEX Plumbing System Design Guide

The U.S. Environmental Protection Agency (EPA) recommends disinfecting all drinking water, typically using free chlorine, chloramines, or other less common methods.

Currently, most potable drinking water in the United States and Canada is disinfected using free chlorine. The second most common method of disinfection is chloramines. The EPA sets a maximum disinfectant level of 4.0 parts per million (ppm) within the water distribution system for water treated with free chlorine or chloramines.

To ensure the reliability of PEX piping systems in hot chlorinated water applications, it is a requirement of the PEX pipe product standard specification ASTM F876 that all PEX pipes intended for use with potable water have a minimum extrapolated lifetime of 50 years when tested following test method ASTM F2023: “Standard Test Method for Evaluating the Oxidative Resistance of Cross-linked Polyethylene (PEX) Tubing and Systems to Hot Chlorinated Water.”

All PEX pipes must be tested and certified by qualified third-party certification agencies to meet the requirements of ASTM F876, including chlorine resistance. The test conditions of ASTM F2023 require that the test fluid has a minimum oxidative reduction potential (ORP) of 825mV. To produce test fluid with this high ORP, third-party test laboratories typically use reverse osmosis-purified water with a free chlorine concentration of 4.3 +/- 0.3 ppm (4.3 mg/L) and pH of 6.8 +/- 0.2, resulting in an ORP of 825 mV or higher. This represents a very aggressive water quality, which gives conservative results in terms of expected pipe lifetime. This test procedure is designed to extrapolate the life expectancy of a hot-water plumbing pipe when used at a domestic hot water temperature of 140°F and a pressure of 80 psi. Continuous recirculation timed recirculation, and ASTM F2023 evaluate traditional domestic conditions. The minimum requirement applies to traditional domestic applications, while the other performance categories are also used in certain situations.

In summary, PEX pipe has shown itself to be resistant to attack from chlorine and chloramines under a wide range of conditions and has performed reliably in all regions of North America.

Keep your ear to the ground and your eye out for some brand pex that has had trouble with treated water. Uponor has had trouble with how they colored the blue and red pipe. They’ve discontinued “baking the color” into the pipe, leaving it subject to failure. Read more about a settled class action lawsuit.

Assessing and Reducing Risk

It is impossible to eliminate the risk of a burst pipe in freezing weather, but some steps can be taken to reduce the risk:

- Never assume that your piping material is immune or has a lower risk of failure.

- Never assume it won’t freeze in your area.

- Avoid installing pipes in uninsulated areas.

- Where possible, install pipes under the slab instead of overhead.

- Use appropriate insulation practices.

- Seal all exterior wall penetrations.

PEX Stress Test

Here’s a nice experiment of PEX freezing under pressure. The pipe measured .624″ wide before the freeze and .630 after being subjected to freezing temps overnight.

Always plan for cold weather.

According to the NOAA, the vast majority of the United States can expect the temperature to drop below freezing at least once a decade, meaning that even if an average winter season consists of mild weather, the odds are that there will be freezing weather at some point during your occupancy. Research by the Insurance Institute for Business & Home Safety found that frozen pipes are more common in warm weather climates due to bad design and installation practices that leave pipes vulnerable to winter weather.

Avoid installing pipes in uninsulated areas.

Many building codes already recommend against or outright prohibit the installation of pipe in uninsulated, but in some regions, it may be allowed. Uninsulated areas may include attics, crawlspaces, overhangs, or exterior walls; when outside temperatures drop, these areas are the first to get cold and present the biggest risk for frozen pipes. Running pipe in the interior, conditioned spaces is always preferred as the air temperature around the pipe will typically be close to the room temperature inside the home.

The Plastic Pipe and Fittings Association (PPFA) is a North American trade association comprised of member companies that manufacture plastic piping, fittings and solvent cements for plumbing and related applications, or supply raw materials, ingredients or machinery for the manufacturing process. Here’s the installation handbook for PEX.

PPFA

With slab foundations, install pipes under the slab instead of overhead.

When dealing with slab foundations, running pipe overhead often requires the installation of pipe in uninsulated areas. By installing piping beneath the slab, the natural geothermal insulation of the ground will typically be adequate to protect against frozen pipes. In addition, running pipes under the slab can benefit builders and contractors, including faster installations and lower installed costs.

When PEX runs through a basement or foundation wall, it must be protected by a rigid sleeve that spans from within the wall to the undisturbed soil in the pipe trench. The purpose of this protective sleeve is to prevent shearing of the PEX tubing at the wall if there is a settlement in the backfill around the wall. When the sleeve terminates inside the foundation or wall, the space between the PEX and the sleeve should be sealed to prevent leakage into the building.4Slab On Grade Installation Note: Petroleum-based caulks or sealants should not come in contact with PEX.

Use appropriate insulation practices.

Appropriate, compatible insulation should be used when pipes are installed in attics, crawlspaces, overhangs, or exterior walls. The insulation must be installed so the pipe sits between the insulation and the interior wall, floor, or ceiling. When multiple layers of insulation are used, the pipe can be installed between two layers of compatible insulation.

A common mistake made by installers is to place the insulation directly against the interior wall or ceiling, with the pipes sitting outside the insulated space, leaving them vulnerable to freezing temperatures. When pipes are installed in overhangs, take extra care to ensure that all exterior walls and floors are insulated and that the pipe is on the interior of the structure relative to the insulation. For added protection, tubing insulation can be used; always confirm the compatibility of the tubing insulation with the pipes used.

Seal all exterior wall penetrations.

Holes or gaps in exterior walls, such as those for cable or electrical penetrations, can allow a more direct path for cold air to reach pipes. Research has shown that the mechanics of freezing pipes can be accelerated by the “wind chill” effect when cold air flows across the pipes. Sealing exterior penetrations and gaps can help prevent cold air from flowing around the pipes.

It’s also important to remember that all pipe materials are vulnerable to freezing, and all pipe and fitting materials can leak after a frozen pipe event. Research by the National Renewable Energy Laboratory found that even PEX piping can burst when installed in short segments or subjected to non-uniform freezing.

Frozen pipes account for less than 20% of piping system failures; material failures such as chlorine degradation are a much more common cause of problems for homeowners. However, frozen pipes are a predictable and preventable problem that builders, contractors, and homeowners can learn to control by following simple best practices.

There are other reasons to maintain water pressure below 80 psi but know PEX is designed to operate best below that threshold. Also, keep your water heater temp below 140º (the PEX manufacturer’s suggestion). Installation matters! Leave plenty of room for the pipe to expand and contract. Insulate the pipe where exposed and if you’re building, ensure the pipe wasn’t stored outside for more than a few days (no more than 30 days is recommended – 6 months at the most).

PEX pipe is freeze-resistant (to a certain extent). Water-filled PEX pipes, allowed to freeze inside a slab or highly compacted soil, may be unable to expand evenly and could suffer damage.

This Article's Footnotes/References

- 1

- 2

- 3

- 4

My whole house is PEX. I’ve had zero issue with freezing, or anything else for that matter.

I read comments on a plumbing forum a few days ago where a plumber stated PEX that repeatedly froze would damage the pipe. I’ve been reading and researching for days now and can’t substantiate that “freeze damage” claim.

However – I did read where the manufacturer (three different makers – actually) recommends to stop the pipe 18 inches back from the water heater tie in – to prevent the pipe from being exposed to the B-Vent on gas heaters.

Pex will burst. We bought a house that had been abandoned for several years in Ohio and I had to fix.18 leaks. Including on in a 1st floor ceiling.

“Pex will burst. We bought a house that had been abandoned for several years in Ohio and I had to fix.18 leaks. Including on in a 1st floor ceiling.“

That must be PEXB.

PEXA is designed to expand.

I have about 300 feet of 3/4 pex in a basement. This is a re- circulation hot water line off of a gas demand hot water heater. On several occasions now the pex line has sprung a leak (away from the fittings) on straight runs. It is a very small hole and the stream of water coming out is very small. Is this a defect in the pex line?

I had the same problems with copper pipes on my recirculation system – new pipes, less than 1 year old. I was suspecting some small debris in the pipes and probable slightly higher or lower spot in the line to cause a tiny eddy or vortex in the water flow at that point.

My entire house is PEX. I’ve had zero issue with freezing, or whatever else so far as that is concerned.

Hi Mr. Smith, I am a small time do – it – yourself handyman, and have been researching a whole lot about this PEX tubing.And from what little I’ve gathered, it’s quite interesting and informative.I also like your comments about the pros and cons of the PEX tubing. I do a whole lot of soldering copper pipes and also work with PVC/ CPVC and other types of piping. And now , hearing from you I’ve decided to do the PEX tubing in some of my jobs. Just love your honesty and straightforwardness on the subject. I believe that if you take the necessary precautions and follow the guidelines , you should have no problems. Thanks a million. God Bless.

Glad to hear! Thanks you!!

Gary, I’m considering running approximately 250’ of 3/4” pex pipe above ground to a boat dock. Main uses are pressure washing, showering and general clean up. Currently have PVC pipe. It burst about every 2-3 years due to freeze. Northwest Alabama is where I reside winters vary.

Is pex pipe my best option? The more I’ve read insulation is a must. Is here any other advice you can give me before I jump into this DIY. Do you recommend a specific fitting?

Anxious to hear from you.

Sunlight and PEX don’t get along well together. When you come out of the ground with it, make sure it’s covered with foam insulation or sleeve it. Running it down there – – you surely want to bury it. North AL is probably about like Memphis (latitude) so your frost line is about 10 inches – get below that and freezing won’t really be an issue. When you come out of the ground it could easily freeze. Assuming you have power down there at the boat slip, if you build a box cover and stub it up into the box, then hang an incandescent bulb (shop light) in the box, the lamp would keep the pipe/hose bib from freezing. My grandfather kept his entire well pump-house (about the size of an out-house) warm with a couple of 200-watt lamps on really cold nights. I have a tankless water heater on my outside wall (here at my house) and on cold nights I hang a light in the tankless heater enclosure to keep it warm.

When I converted my small house to PEX, I used a shark-bite connector bought from Amazon to connect the PEX to the copper main line. It’s super easy to connect so I was a tad suspicious, but has held up for over 5 years now.

I have 5/8 PEX in my basement concrete floor slab used for hydronic heating. The PEX is filled with water, not a mix of antifreeze. We live in upper Wisconsin where the temps can get down to -30 degrees or worse. We will be leaving for the winter with the whole house central forced air unit will be on and set at 55 degrees. This includes the basement where there is duct work. Will I need to turn on my hydronic system on to avoid the PEX from freezing if the Central heat is on @ 55 degrees?

My neighborhood had 2 builders.. One builder, mine, used pex and the other used copper. 3/4 of the houses that used copper had a busted pipe during the Texas freeze this week due to no power. Not one pex home had a burst pile.hope that helps with some data.

I’ve experienced similar results. Thanks Jim.

Is there Pex for hot water and pex for cold water? Or can I use the same pipe for both?

The color simply helps identify the hot/cold. The pipe are the same.

Is type A PEX better to use to plumb I live in a float home on a Lake the plumbing used to be in the Attic copper pipe it had froze several times so the plumbing was moved to on the wall inside the home and it has some copper,red and blue pex,with 2 feet of some clear or opaque tubing would type A be best for the replumb as temps fall well below 0

PEX A is more prone to chemical leaching from the manufacturing process. I recommend PEX B for potable water lines…also, B is easier to work with…look here: LINK

I have a question about running pex from my pump house up hill to the house,,but not able to dig down 42 inches, but I plan on draining and blowing it out with air before winter will the pex be ok? The house is in upper west Illinois, plan to bury it about 2 feet. Ty