Estimated reading time: 5 minutes

I recently conducted a poll within my 9,000+ member Facebook Group and discovered that 88% of inspector members encounter at least one home per week with broken window seals. This issue is pervasive across the United States, posing challenges for all window manufacturers. It’s worth noting that older homes with aged windows are particularly susceptible to failed seals, an observation consistent with my 50 years of experience in construction coaching in Mississippi.

The First Step in Repairing or Replacing a Broken Window Seal: Check the Warranty

Most manufacturers offer a guarantee against insulated glass failure. Warranty periods can vary but typically range from 10 to 20 years. It’s crucial to check this information first, especially in an older home.

Causes of Window Seal Failure

Window seals can fail due to various factors, including weather conditions, poor manufacturing practices, product age, and acidic cleaning solvents. In Mississippi, our hot climate and fluctuating atmospheric pressure seem to expedite this wear and tear. Sunshine is usually the most prevalent culprit, so south and west-facing windows usually fail first.

Understanding Solar Pumping

A phenomenon known as “solar pumping” hardens the sealant forming the window seals. The process starts when sunshine heats the air inside a double-paned window, causing it to expand. This expansion forces air out through the semi-permeable seals. Later, the window contracts, drawing air and humidity back in.

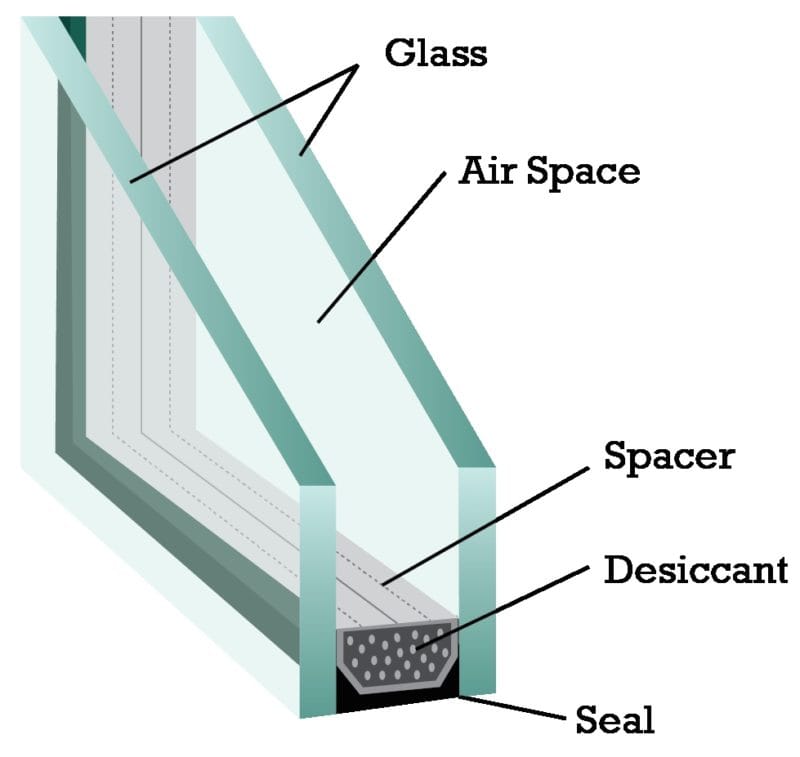

The Role of Desiccant

Manufacturers place silica pellets inside an aluminum perimeter strip (the spacer bar). The silica acts as a desiccant to absorb moisture. When the seal fails, moisture penetrates this space, saturating the desiccant and causing condensation along the window’s perimeter.

The Cycle of Damage

Day after day, year after year, this cycle of expansion and contraction stresses the window seal. Given enough time, the desiccant becomes overloaded, contributing to the overall failure.

Certifications and Window Durability

While there may not be explicit building codes addressing window seal quality, it’s important to note that ENERGY STAR-certified windows undergo stringent testing. These tests aim to minimize seal failure and gas loss by evaluating the window’s resistance to extreme temperature swings, high humidity, and UV radiation.

Climate-Specific Advice

If you reside in a climate with extreme temperatures or high humidity, as we do in Mississippi, replacing the window is often more beneficial than repairing it. The insulated glass will protect your home from temperature fluctuations, making your living spaces more comfortable and reducing energy bills.

Identifying the Manufacturer

If the window lacks identifiable markings, finding warranty information becomes a challenge. Always request this information when purchasing a new construction or undergoing a home remodel.

The easiest way to identify a window is by directly locating the manufacturer’s name on the product. Acron, Biltbest, Caradco, Hurd, Marvin, Malta, Oldach, and others stamp their name on the window hardware – generally on the handles, sash locks, or other window or door hardware.

Look carefully inside the insulated glass between the panes. You may find information embossed directly onto the spacer bar.

Companies like Andersen, Pella, Better-Bilt, Shelter, Outlook, and Windsor will have their names “etched” in the corner of the glass; other companies like Crestline, SNE, and Vetter are all known not to place their names on units anywhere…instead, they use a string of letters and numbers on their products. You’ll have difficulty identifying the manufacturer unless you know exactly what these letters and numbers mean.

Everything Has A Life Cycle

A general expectation for the lifespan of double-insulated windows is around 15 to 20 years. Some high-quality windows can last up to 25 years or more, especially if they are well-maintained.

Factors that can affect the life cycle include:

- Climate Conditions: Windows exposed to extreme temperature fluctuations, high humidity, or strong UV radiation may have shorter life cycles. For instance, in a hot and humid climate like Mississippi, the stress on window seals can be particularly intense, reducing the life expectancy of the window.

- Maintenance: Harsh chemicals used when cleaning and caring for windows may affect the life cycle.

- Quality of Installation: Poor installation can result in a reduced lifespan as issues like air leakage or water infiltration can occur more easily, potentially leading to premature failure.

- Building Codes and Standards: Failure to adhere to general building standards and practices can affect how long a window lasts.

- Warranty: Most manufacturers offer warranties that may cover the window for anywhere from a limited period up to the window’s lifetime. While not a guarantee of lifespan, the length and comprehensiveness of a warranty can indicate the manufacturer’s confidence in the window’s durability.

My Recommendations

If the window lacks warranty coverage, consider replacing the insulated glass unit within the sash (the window frame). Quick fixes like “defogging” don’t address the root cause of the failure and often lack a repair warranty. I strongly recommend turning to a professional for this task. The window replacement cost varies based on size, style, and location.

Join my 9,000+ member Facebook group for homeowners and inspectors.

- - - - - - - - - - - - - - - - - - - - -